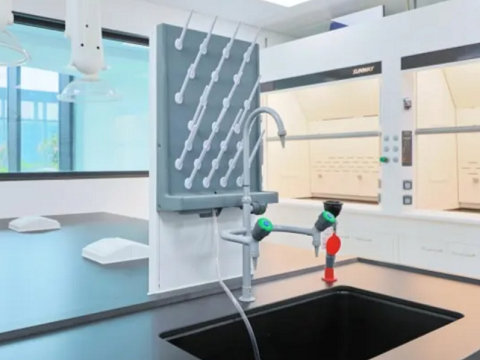

Lab drying racks:

Lab drying racks, vital for drying glassware post-cleaning, shine with PP (polypropylene) variants leading the way. PP’s inherent resistance to chemicals—acids, alkalis, solvents—and moisture makes these racks ideal for harsh lab environments, outperforming materials prone to rust or corrosion. Lightweight yet durable, PP racks feature slotted shelves or pegboards that maximize airflow, speeding drying. Their smooth surfaces resist staining and are easy to sanitize, reducing contamination risks. Adjustable pegs accommodate diverse vessel sizes, from test tubes to flasks. Widely used in chemistry and biology labs, PP drying racks balance functionality and longevity, ensuring reliable, low-maintenance performance in daily workflows.

Core materials and properties

- High-density polypropylene (PP):

PP material exhibits exceptional resistance to strong acids, alkalis, and corrosion, making it ideal for prolonged exposure to chemicals. Its semi-crystalline structure provides high surface stiffness and scratch resistance, while its low density (0.89–0.92 g/cm³) ensures lightweight and easy portability. - Thermal stability:

PP has a Vicat softening temperature of 150°C and a melt temperature range of 180–275°C during processing, allowing it to withstand typical high-temperature laboratory environments.

Design and functional features

- Modular structure:

- Removable Drip Rods: Compatible with beaker rods, long/short test tube rods, and other accessories for flexible configuration.

- Drainage system: A base tray with drainage holes and arc-shaped drip grooves prevents water accumulation and simplifies cleaning.

- Installation options:

- Wall-mounted (space-saving)

- Benchtop (portable) designs to suit different lab layouts.

- Innovations for enhanced drying efficiency:

- Temperature control & airflow optimization: Select models include fans and heating elements to accelerate drying via adjustable airflow (ambient or heated) while protecting glassware from damage.

- Staggered air vents: Arrayed on drip columns to balance air pressure and expedite moisture removal from glassware interiors.

Applications and industry coverage

- Medical & biopharmaceutical: Drying sterile equipment in compliance with GMP cleanliness standards.

- Food chemistry & environmental protection: Corrosion resistance suits labs handling organic solvents or strong acids/alkalis.

- Education & research institutions: Universal design meets routine needs, such as glassware drying in university chemistry labs.

Purchasing guidelines and market Insights

- Specifications:Common models include 27-rod and 52-rod configurations, with dimensions like 630×450×120mm (L×W×H); customizable for lab capacity.

- Cost & lifespan:PP material ensures a lifespan exceeding 8 years with minimal maintenance, ideal for long-term investment.

Technological trends

- Smart upgrades:Integration of temperature sensors or Iot connectivity for remote monitoring and automated drying processes.

- Green manufacturing:Use of recyclable PP materials to align with eco-friendly policies and reduce carbon footprints.

Lab drying racks

- With their corrosion resistance, lightweight design, and modularity, are indispensable in modern laboratories.

- Users should prioritize specific experimental needs (glassware types, spatial constraints) and vendor support to maximize efficiency.

- Future advancements will focus on smart and eco-friendly technologies to drive industry evolution.